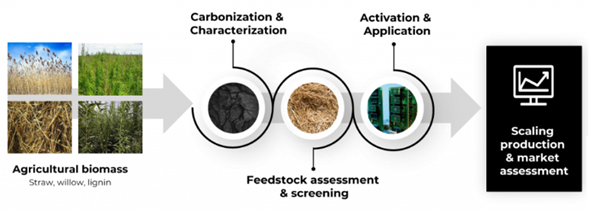

BioCarbonValue project explored high-value functional carbon materials from agricultural sidestreams

ProjectsThe two-year Business Finland Co-Research project BioCarbonValue aimed to develop alternative carbon materials to replace fossil-based carbon in high-value applications such as energy storage systems, biocomposites, and purification processes. Biocarbon (or biochar) production is seen as a newly emerging industry that benefits both the climate and the environment while offering multi-billion euro business opportunities for companies.

The foundations of the BioCarbonValue project were formed already during the Vihreän kasvun biokylä-project (09/2019 – 08/2021) by the collaborative efforts of LAB University of Applied Sciences, LUT University and City of Heinola, focusing on the sustainability and economic aspects of the supply chain for straw and agricultural waste from fields into a biorefinery. The project stakeholders included Fortum Bio2X and approx. 500 farmers of the Päijät-Häme region in southern Finland. In addition, the challenges and limits for the utilization of field biomass were advanced and clarified to support in future initiatives like the BioCarbonValue project.

VTT Technical Research Centre of Finland and LAB University of Applied Sciences were the primary research partners of the BioCarbonValue project, complemented by nearly ten other partners ranging from large industrial companies to innovative SMEs and even a municipality – all joined together with the fundamental aim of supporting the development of a business ecosystem around agro-sidestreams and the establishment of a viable value chains for biocarbon production towards high-value applications.

ExpandFibre team invited Virpi Siipola, Senior Scientist at VTT, and Tuomo Hilli, CTO and Founder at Elementic, to discuss the project that ended in December 2024, its highlights as well as the next steps for any future work related to the theme of the project.

The final seminar event of BioCarbonValue was successfully organised in November 2024 at Wanha Walimo in Lahti, Finland. The event’s agenda included presentations from key members of the project consortium including researchers from both LAB and VTT as well as from Chempolis, City of Heinola and Neova Group. According to Virpi the final reporting for the project’s funding body Business Finland is expected to be completed by end of April 2025, after which a public summary of the project and its results can be published for all interested parties.

As the company founder and CTO, Tuomo Hilli explained that Elementic (previously known as Fifth Innovation) was very happy to be part of the BioCarbonValue consortium, being an innovative SME company operating in the field of novel carbon-storing construction materials. Tuomo described the seven-year old company’s current status: “It’s debatable if we’re still considered as a start-up company, although we’re still very much operating like one. At the start, we were more of a consultancy company, but we have slowly focused our activities into research and actually manufacturing innovative carbon materials, where we continue seeing great potential. We have specialised in developing a versatile and durable pure carbon material that is suitable for use in both the exterior facades and interior spaces of buildings. As of now, we’re still operating in somewhat extended laboratory-scale, but we’re finalising the work on our upcoming pilot-scale facility in Pirkanmaa, Finland. We hope to start the pilot-scale production at our new facility by end of 2025 nearly 100x our current production capacity. We’re also targeting increasing our team from the current six people to 10 people by end of 2025, which we’re very excited about.”

Reflecting on the ended project

As one of the chief investigators of the project, Virpi Siipola took a trip down memory lane, looking back on the successful two-year collaboration: ”Previously LAB University of Applied Sciences had developed the Vihreän kasvun biokylä project based on the utilization of straw biomass, which provided a lot of knowledge and insights for the formation of the BioCarbonValue Co-Research project. Looking back, the Co-Research framework of Business Finland proved to be extremely suitable for our research purposes, lacking the heaviness of the Co-Innovation project framework. Also, this way we got to disseminate our project results more openly, benefiting the entire biocarbon sector. Actually, we’re already scoping for a new Co-Research project based on the highly positive experiences of BioCarbonValue.”

Tuomo continued: “We have previously taken part in Co-Innovation projects, and I’m happy to complement Virpi on the extremely well conducted BioCarbonValue project. With a relatively small investment we were able to generate an immense amount of data. I’d say that the input/output ratio of this project was especially high, all things considered.”

Virpi continued: “We had an ambitious project plan, and we put in a lot of work during the project. Actually, we’re still processing parts of the gathered data, and of course we’re also still preparing scientific articles based on our key findings. Overall, this was a huge learning experience for me personally as well.”

Tuomo added: ”For me one of the strengths of the project was that the research questions were kept on a broad level, instead of diving too deeply into a specific research area. This gives us the great opportunity to potentially dive deeper to a specific topic later on, if we wish to do so.”

Virpi analysed the situation further: ”To simplify the overall picture, forest-based side streams have traditionally been at the core of biocarbon initiatives in Finland. However, we need to dramatically broaden our raw material portfolio as more and more industries are driving the demand of biocarbon – as an example, steel industry is looking very heavily into replacing fossil-based carbon with biocarbon. Agro-based biomasses like straws have their own challenges regarding e.g. high ash content and other possible impurities, thus we can’t simply substitute one bio-based side stream with another without properly considering the processing needs for different raw materials. We have to also consider geographic differences in available biomasses. For example, if we look at Asia, where agrobiomasses and agro-based side streams play very important roles, whereas forests have a much lower role, in comparison to Northern Europe. Politics and major world events also impact global supply chains. For example, currently the situation in Finland is challenging as wood imports from Russia have stopped completely due to the ongoing war in Ukraine, having a direct impact on the availability of biocarbon raw materials locally here in Finland.”

Tuomo noted: ”Luckily, we’re finally waking up to the fact that it makes more sense to refine biomass towards higher-value applications instead of merely burning it for energy. As an anecdote from my previous career in the industry working for Valmet, we estimated that all the biocarbon in Finland would not be enough to fire up the blast furnaces at SSAB Raahe mill – giving much needed context to the big picture regarding biocarbon availability in Finland.”

The example discussed by Tuomo is presented in full detail in the VTT publication “Replacing Coal Used in Steelmaking with Biocarbon from Forest Industry Side Streams” from 2019.

Shortly on the practical experiments of the project

Virpi proceeded to explain in a bit more detail about the practical experiments carried out during BioCarbonValue: “For biocarbon production we conducted traditional slow pyrolysis in three different temperatures, carefully analysing all the generated pyrolysis gases. The biocarbons were refined into active carbons and tested in several use applications incl. water purification and biocomposites. Straw-based lignin, supplied by Fortum, was one of the special raw materials for this project, and we tested its suitability for energy-storage applications. We started by chemically activating the lignin and finally testing it in battery applications, which yielded very promising results. Overall we produced multiple different types of carbon materials including biocarbons and chemically activated carbons.”

Tuomo continued: ”As mentioned, I really appreciated that the research and in particular the experimental work did not focus too deeply into a specific value chain but instead was quite wide in its scope. Even though I already had an extensive background with this topic, I certainly learned a lot from the project and its results. As SME company, we really appreciated that we did not need to invest too heavily our limited resources into the project, and we feel, that we really gained a lot from the project. The company partners had excellent collaboration throughout the project, and luckily there were no great conflicts between partners. All companies had similar possibilities to exploit the project’s results and develop their own value chains further.”

Next steps & looking ahead

Virpi shared initial plans on the continuation of the work: “We have already started collecting ideas for continuing the work of BioCarbonValue. As mentioned, the scope of the project was fairly wide by choice, so there are plenty of future possibilities to go deeper into a specific topic with the next project or even multiple projects, depending on the available funding. Regarding future funding opportunities, we’re also waiting to hear more about the new Business Finland Veturi programmes and what topics they have highlighted in their RDI roadmaps. As an example, we have already been discussing a project idea together with Aalto University related more specifically to the application area of building materials. Lot of project preparations and planning are also taking place with the energy storage application area, and I’ve been personally involved with multiple discussions related to that specific topic. Overall I’m very happy that the interest and knowhow related to biocarbons and activated carbon materials has raised to the next level within the past few years. To close, I also want to point out that the expertise around this topic has greatly grown also inside VTT and the BioCarbonValue project helped to create an EU regional and structural policy programmes (EAKR) funded HATTU-project, which enables us to expand our piloting capacity further for the production of biocarbons.”

Tuomo also added his thoughts on the future: “I personally see biocarbon as a vital tool for alleviating the global challenges related to carbon materials and related emissions. With biocarbon we’re essentially turning carbon into a more stable form. For example, if we manufacture ethanol or food, only a small part of the carbon is utilized, while majority is discarded. For example, one kilogram of our Elementic material corresponds to 3 kilograms of carbon storage that is stable for a significantly long time. In the big picture we need to see a big change in how the industry-at-large views carbon not just as an energy source but as a truly strategic material. Especially here in Northern Europe we need to get active in utilizing our vast renewable natural resources for biocarbon applications and catch up with the Asian countries, who have pioneered this field for a long time manufacturing biocarbons from e.g. coconuts.”

BioCarbonValue project factsheet:

Project duration: 01/2023 – 12/2024

Project budget: EUR 1,2 million

Project type: Business Finland Co-Research (funding through ExpandFibre partnership call in 2022)

Research partners: VTT Technical Research Centre of Finland (coordinator) and LAB University of Applied Sciences

Other partners: Carbo Culture Oy, Carbofex, Elementic (previously known as Fifth Innovation), Fortum Bio2X (Chempolis replaced Fortum Bio2X during the final stage of the project), City of Heinola, Neova Group, Premix, PUHI Oy and Sumitomo SHI FW

Project website: https://www.biocarbonvalue.fi/