ExpandFibre ecosystem member CH-Bioforce boasts unique biomass fractionation technology

Members NewsAn ExpandFibre ecosystem member CH-Bioforce is a Finnish company known for one of the leading technologies for a gentle extraction of all the main components of biomass in one process. The end result are pure biomaterials that provide new options as sustainable feedstocks for industries developing for example chemical, textile and packaging applications.

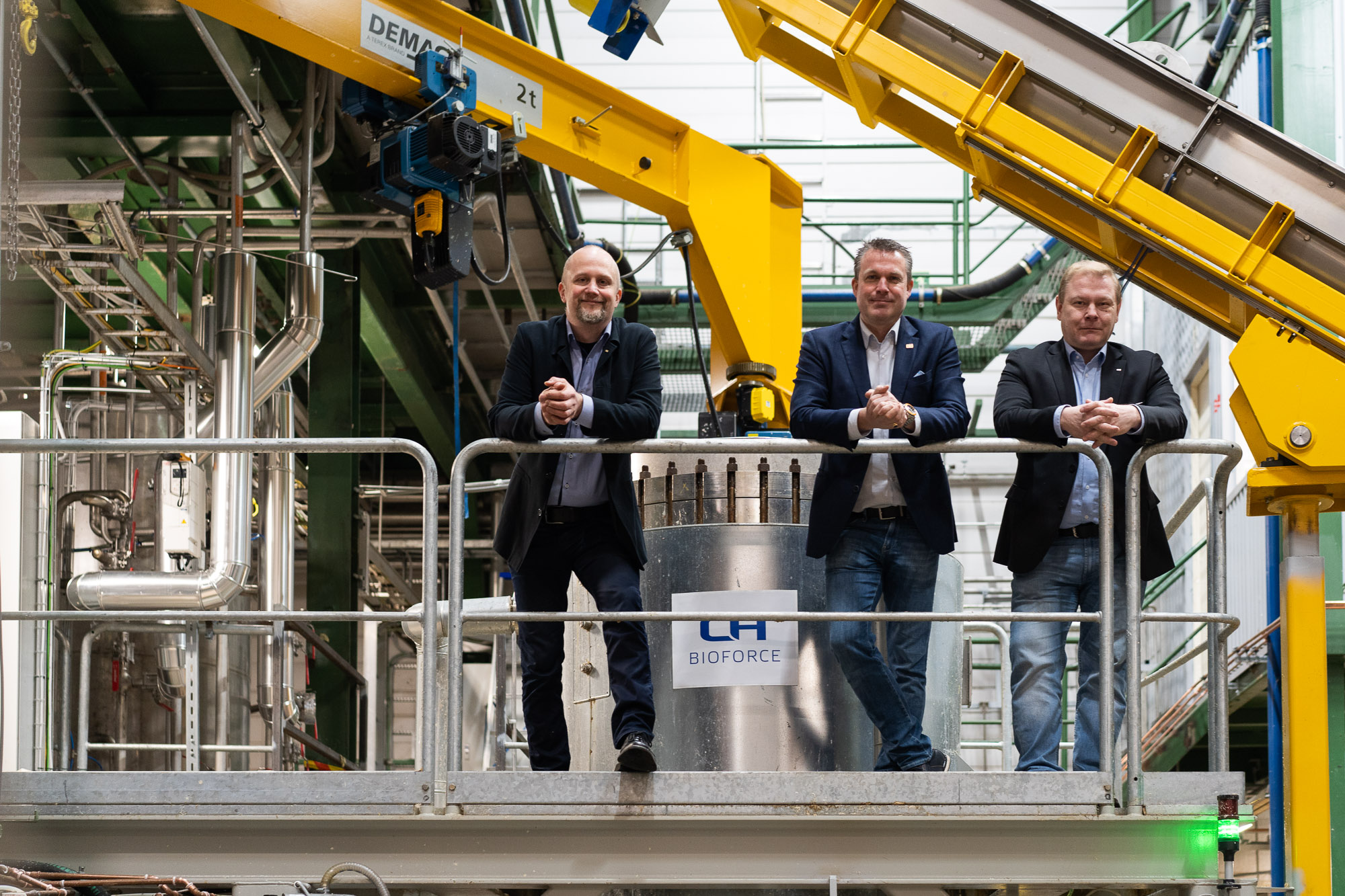

We talked to the co-founders of CH-Bioforce Lari Vähäsalo (R&D Director), Sebastian von Schoultz (Chief Business Officer) and their CEO Petri Tolonen who told us more about the history, current situation, and future plans of this innovative company.

Breakthrough technology in wood chemistry

CH-Bioforce got its start in a garage in a small Finnish village, where three friends, namely Lari, Sebastian and Nicholas Lax (currently CTO at CH-Bioforce) with wood and paper chemistry background set up a small home-made pressure reactor and started to experiment with unconventional chemistry with the aim to enhance the existing pulping processes. Eventually, out came pure hemicelluloses, sulfur-free lignin and very pure cellulose. Today, the revolutionary biomass fractionation technology, BLN-fractionation developed by BLN-Woods, is being commercialized by CH-Bioforce.

Today a company employing more than 10 persons, CH-Bioforce currently has their demonstration plant in Smart Chemistry Park in Raisio, where there are a lot of synergies with the other companies. As opposed to the 50% or even less of biomass usage in traditional cellulose plants, the CH-Bioforce technology can fractionate 95% of the biomass components, which can be converted into high-quality biopolymers such as dissolving pulp, hemicellulose and sulphur-free lignin. CH-Bioforce continues to deliver material samples to various customers for further testing and application development, sharing the driving force to develop fossil-free products for the various end users in chemical, textile and packaging industries.

The fractionation technology is not too picky about the raw materials as long as it is something that grows — any old saw dust and residuals from chipboard factories are all welcome for fractionation. From the point of view of reducing CO2 and for example phosphate emissions, collecting straw from the fields and common reed from the sea and lakes for fractionation is also a feasible and sustainable possibility in the future.

“Bioforce of nature” is taking steps forward

CH-Bioforce is now looking into securing more funding to build an industrial-sized biorefinery plant which is planned to be up and running by 2024. As the only actor in Finland to be able to produce polymeric hemicellulose at this scale, CH-Bioforce welcomes collaboration with the ExpandFibre ecosystem members and is looking forward to partner with end-product developers to validate their technology. Lari Vähäsalo sums up: “I see it as essential that all the members of the ExpandFibre ecosystem are committed to get genuinely industrial business out of this collaboration. This should be the main incentive in the minds of all members.”

Photo: Nicholas Lax, Sebastian von Schoultz and Lari Vähäsalo.

More information: https://www.ch-bioforce.com/