NUMOBIO project set out to accomplish substantial leaps in digitalising biocomposite design for optimised development of new materials and products

ProjectsBusiness Finland funded two-year NUMOBIO project (Advanced NUmerical MOdelling for rapid development of BIOcomposite applications) ran from August 2021 until end of 2023, exploring important topics related to the modelling and testing of natural-fibre reinforced composite materials, also known as biocomposites. Some of the key outcomes of the project included a substantial set of experimental data on biocomposites collected from industrial use cases within the NUMOBIO consortium, and a successful demonstration of individual fibre testing for short wood-pulp fibre strength and fibre-matrix adhesion.

NUMOBIO project’s key research partners Tuukka Verho, Researcher at VTT, Pasi Kallio, Professor at the Faculty of Medicine and Health Technology at Tampere University, and Essi Sarlin, Professor at the Faculty of Engineering and Natural Sciences at Tampere University were joined by Kirsi Hirvonen, Development Manager at Metsä Fibre, to reflect on the concluded project and its primary outcomes.

Background to the project

Tuukka reflected on the path leading to the creation of the NUMOBIO project: “A dedicated material modelling cluster had already been active and developing at VTT, prior to NUMOBIO, utilising advanced numerical analysis and other computation tools to digitalize material design, in hopes of speeding up the development cycles overall and thus bringing competitive edge to industrial operators. During an internal project at VTT multiple research teams came together for material research topics on biocomposites coupled with aspects from artificial intelligence. During this project we were presented with the possibility to apply for funding from the Business Finland’s Veturi scheme linked to the ExpandFibre Ecosystem. Marko Mäkipää and Timo Avikainen from the VTT team were elementary in getting the ball rolling towards the creation of NUMOBIO. From the start it was clear that we wanted to get Essi and Pasi from Tampere University involved in the project in order to gain a lot of crucial new understanding on the topic.”

Essi continued from Tampere University’s point of view: ”As we started building the project plan, we were already involved with a natural fibre themed EU project, which was highly complementary and compatible with the topics of NUMOBIO.”

Pasi reflected further: “We had previously worked extensively with longer fibres, so shifting the research focus towards much shorter wood pulp fibres was a new and exciting territory for us.”

Kirsi added a perspective from the industry: “Biocomposites were one of the seven theme areas on the ExpandFibre R&D&I roadmap, and we at Metsä Fibre were very interested to follow development paths related to novel fibre-based products in general. Although biocomposites were not at the core of our expertise, we were interested in testing out VTT’s modelling tools and reaching out to new partners through the NUMOBIO consortium.”

Tuukka continued to offer additional insights on modelling in general: “Modelling tends to focus on relatively simple and continuous structures such as carbon fibres, which are homogeneous and straightforward in their assembly. With much shorter wood-fibre composites, we need to place special emphasis on what happens at the end of each fibre, as every fibre is different, bringing a lot of added complexity in relation to an ideal modelling situation. For example, glass fibres are very straight and highly uniform in their structure having a rounded cross section. Wood fibres on the other hand have a very flat cross sectional profile, also adding complexity to the modelling work. Perhaps due to these challenging attributes, modelling of shorter natural fibres, such as wood pulp fibres, has had much less emphasis than carbon fibres or glass fibres.”

Pasi added: “In order to build the complex models, we needed lots of experimental data. This meant gathering intricate strength data from single wood fibres, in addition to analysing the interfacial forces between wood fibres and polymers – the two key components in biocomposites. There simply were not many readily available technologies or methods for carrying out these measurements.”

Kirsi was particularly impressed by the successful strength measuring of a single wood pulp fibre, demonstrated during NUMOBIO: “I’m confident this could open up further interesting possibilities also in other wood pulp related projects in the future.”

Essi continued on the importance of modelling: ”If we truly want to understand, for example, why a certain surface treatment works and another one doesn’t, we need fundamental understanding on the interfaces between different materials. Our vision is that modelling will unlock vast additional insights into this topic.”

Tuukka concluded the topic: ”One of the central research questions for us has been to unravel the origin for the strength and stiffness provided by natural fibres in biocomposites. When measured a single fibre is not that strong, but in a biocomposite matrix they provide the crucial mechanical strength properties, which is fascinating.”

Key outcomes of NUMOBIO project

Tuukka opened the discussion on the outcomes of the project: ”We learned that bio-based short fibre composites were very challenging to model with the available tools, which was a somewhat surprising finding. For us this only highlighted further the need to develop additional modelling tools specialised for short fibres. The modelling of various processing steps, especially extrusion, proved to be very important and interesting for the industrial partners in particular. Looking back, a majority of the project’s duration was used working with existing tools, and perhaps less emphasis was placed on developing completely new methods.”

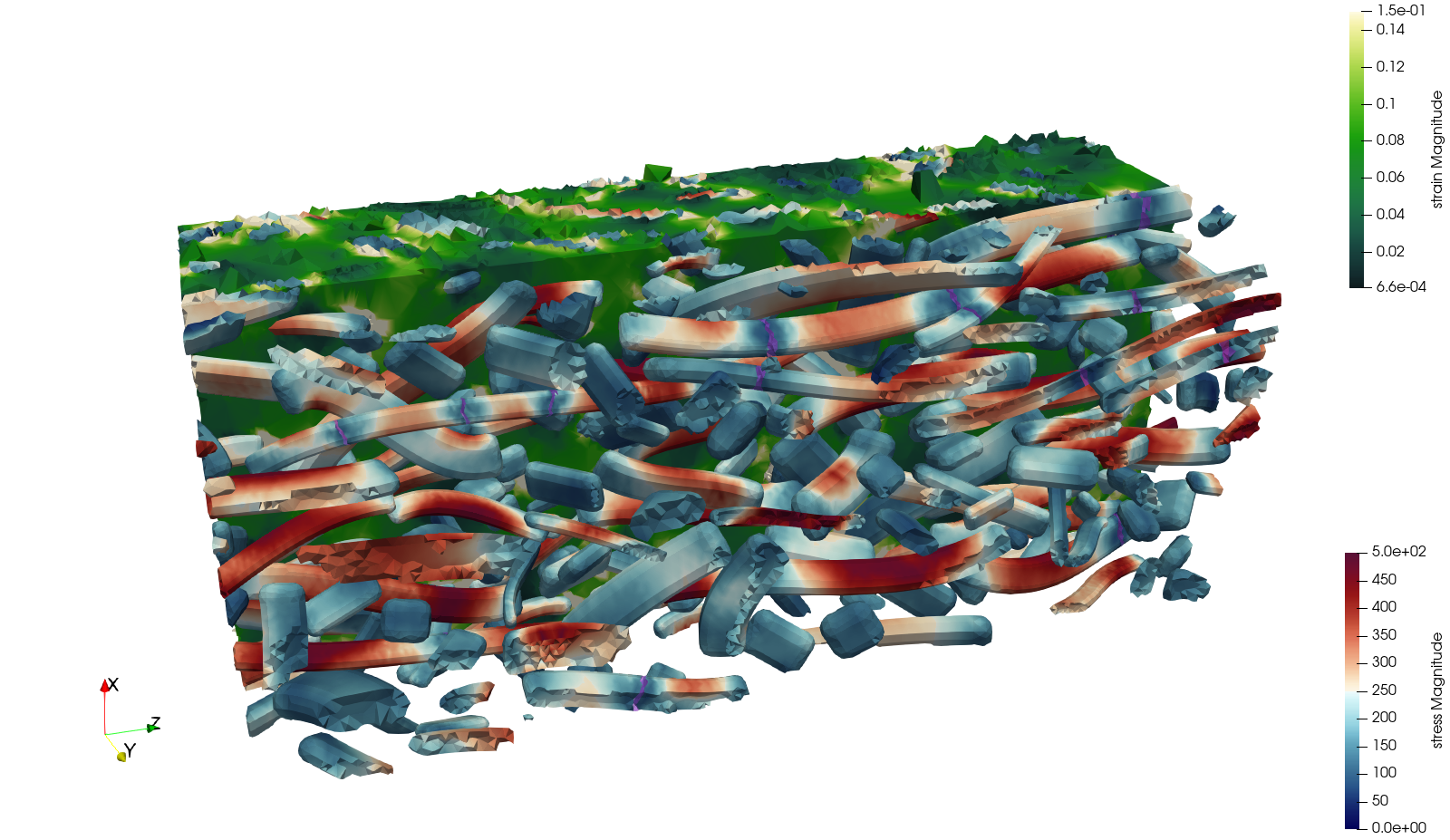

“We were able to demonstrate a detailed modelling chain with three separate levels, which was an important outcome for the project. We were also able to model key processing steps such as injection moulding and extrusion with different wood fibres, both bleached and unbleached. Changes in fibre lengths across processing steps, degradation of polymers and the development of mechanical properties were all key findings for us”, as Tuukka explained.

Pasi wanted to pinpoint four key points: ”Firstly, the experimental methods played a key part. We measured the very short pulp fibres with added help from micro-scale tools instead of adhesives, which can easily impact the characteristics of a single fibre. Thankfully during NUMOBIO we were able to further develop the micro-scale tools for single fibre measurement. Second point is the three-dimensional imaging of a single wood fibre, creating a 3D reconstruction of wood fibre’s structural elements – a result that could be beneficial also for other areas of research in the future. Thirdly we focused on successfully measuring the interfaces between wood fibres and polymers, based largely on a novel concept co-developed with KTH in Stockholm. I’m glad that this work has continued also after NUMOBIO. Last point relates to increasing the level of automation for the single fibre measurement method, as we’re still too heavily dependent on the role of the operator. Although we were able to increase the automation level during the project, we unfortunately did not reach all of our goals for this particular target.”

Essi continued: ”From my perspective the vast possibilities for characterisation of materials are fundamentally important when looking back at the main outcomes of the project.”

Kirsi concluded on the outcomes: ”We at Metsä Fibre recognised the potential of VTT’s ProperTune® modelling concept as a beneficial future tool for us, and in general we were very grateful for the added overall understanding on the topic of biocomposites provided by NUMOBIO.”

Next steps & looking ahead

The interviewed NUMOBIO partners all agreed that the concept behind the project was unique and were hoping to continue the fruitful collaboration that developed during the project.

Tuukka offered insights on additional future activities related to NUMOBIO: ”Together with Tampere University we at VTT are involved in an international research collaboration of flax fibre composites involving numerous interesting partners. In addition we’re preparing for future EU projects in which the models develop during NUMOBIO could be highly beneficial.”

Pasi continued: ”At Tampere University we have very strong international networks on this topic including research collaborations with Belgium, France and Italy, for example. I’m happy that multiple research groups internationally have recognised the potential benefits of the developed measurement methods, and we’re busy preparing for future initiatives to take the research and knowledge even further. In addition to academic collaboration, we’re also hoping for an even stronger collaboration with the industry in this topic.”

Essi commented further: ”As NUMOBIO was a Business Finland funded initiative, there was understandably a strong focus on the Finnish industry. However as a researcher finding new collaboration partners might be a lot easier outside of Finland. Thus, I’d be very happy to see more activity from the Finnish industry in these more research driven initiatives.”

Tuukka picked up on Essi’s comment: ”I fully agree with Essi, and the main challenge is that there is only a limited number of Finnish companies focused on biocomposites and their development. Looking towards EU gives many more opportunities for biocomposite related topics.”

Kirsi concluded the discussion: ”As ExpandFibre ended in August 2024, we will reassess the collaboration with the main research partners of NUMOBIO, and of course continue our own efforts at Metsä Fibre on wood fibre based topics.”

Photo credit: VTT

NUMOBIO project fact sheet

Project duration: 8/2021 – 12/2023

Project funding: Business Finland

Project partners & roles:

-Research partners: VTT (project coordinator) and Tampere University leading the research with additional involvement from international research partners KU Leuven (BE) and KTH (SE).

-Industrial partners: Metsä Fibre as the Veturi company & supplier of wood-fibre raw material; Profcomp and Elastopoli as biocomposite production and process knowledge specialists; Parlok as the automotive and transportation industry use case; Block Solutions, Primo and Konto as the construction industry use cases; Nature Cutlery and Huawei as the electronics and consumer durables use case.

-Industry dissemination partner: Muoviteollisuus Ry.